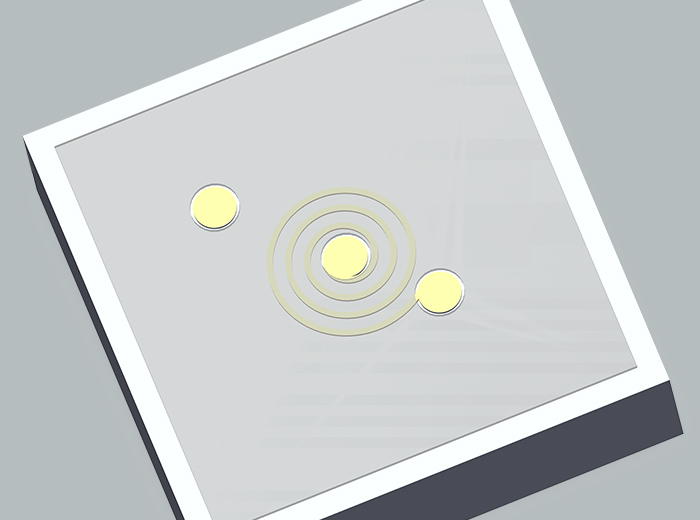

Inductor Coils

SemiGen's Inductor Coils are manufactured using our thin film process on quartz substrates. The precision photolithography and non-chemical etching process provides clean edges to assure uniformity from coil to coil. By using quartz and applying a polyimide coating we produce a device that eliminates the need for conformal coating or staking. Inductors can be epoxied down with nonconductive epoxy and the wire bonded for connection.

Inductor Coils

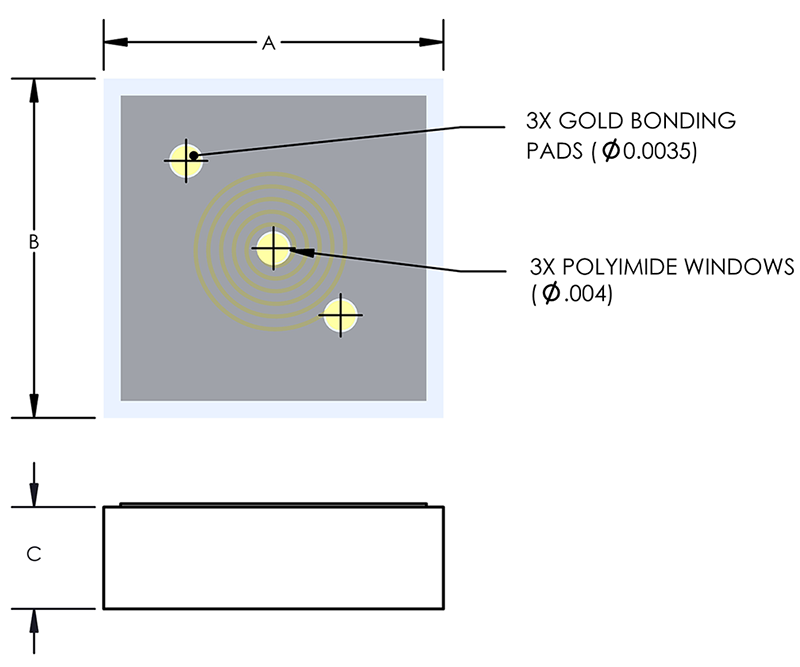

Dimensions: Inches

| Part # | DIM "A" MAX | DIM "B" MAX | DIM "C" MAX |

|---|---|---|---|

| SG100 | .030 | .030 | .012 |

| SG101 | .030 | .030 | .012 |

| SG102 | .040 | .040 | .012 |

| SG103 | .040 | .040 | .012 |

| SG104 | .040 | .040 | .012 |

| SG105 | .045 | .045 | .012 |

| SG106 | .055 | .055 | .012 |

| SG107 | .065 | .065 | .012 |

| SG108 | .075 | .075 | .012 |

| SG109 | .085 | .085 | .012 |

Features:

- NO need for “Staking” Coil

- Passivated Protective Coating Over Coil

- Dimensional Uniformity

- Planar Solid Structure Coil

- RoHS Compliant

Applications

For use in Attenuators, Amplifiers, Switches and Filters in replacement of conventional wound coils. Operating frequency is up to 20GHz.

Downloads:

Resource

.png)