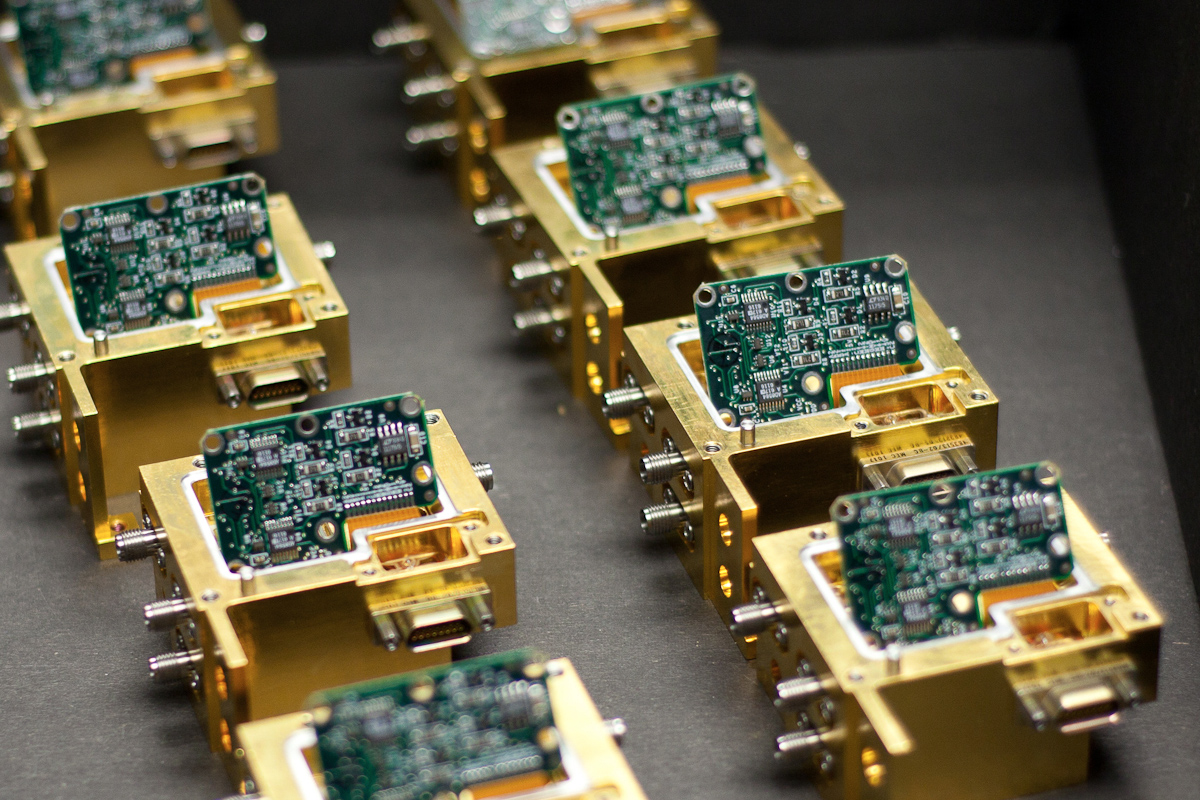

Five Common Wire Bond Failure Modes to Look for to Ensure MIL-STD Qualification

In our Tech Brief "Tips for Increasing Yields When Wire Bonding Small Mesa Chips" we cover a variety of topics from tools to process development. But one of the more critical tips is about how to spot wire bond failures. In this blog, we've captured the five most common failure-modes so you know what to look for early to ensure your best chance of being qualified to the rigorous MIL-STDs you need to meet.

1. Cratering and Peeling

Due to the high pressures and heat involved with thermocompression, which also impacts thermosonic wire bonding to some degree, cratering and peeling of the wire bond pad is possible. This failure mode may lead to increased resistance from the die to the package, and lead to heat stress and performance issues with high-speed signals. Cratering and wire-bond peeling can also result in complete disconnection over time and stress.

2. Over-stretching and Over-twisting

A bond wire that is stretched too far and experiences too much pressure at a connection point may break at the connection point or along the wire length. Moreover, if a bond wire is bent too tightly or twisted beyond specification, breakage can also occur. As bond wires are very fine and hardened to improve consistency, they are also brittle and any significant force may lead to a fractured or broken wire bond. Fractures can increase resistance and lead to failure due to further damage from localized heating.

3. Untamed Tails

If a wire bond is not cleanly cut on each end, the wire-bond tail may extend to another bond pad, bond wire, or trace on the die itself. Beyond increasing the parasitic inductance and capacitance of the wire bond, inconsistent bond tails can cause electrical shorting and increased crossover/coupling effects in high-speed or high-power circuitry. Shorting, arcing, and cross coupling can reduce performance and damage, or even destroy, a die.

4. Poor Adhesion

If the wire-bond and bond-pad weld do not cause adequate mechanical adhesion and electrical connection, a weak bond can ensue. A weak bond may have greater parasitic inductances, capacitances, and resistance than is specified by the packaging process. Also, localized heating from increased resistance can further weaken the bond and eventually lead to complete failure.

5. Missed Targets

Alternately, a wire bond may land partially on a bond pad, between bond pads, or even bridge bond pads. Any of these occurrences can lead to shorts, weak bonds, poor welds, and a wire-bond disconnection. Essentially, a wire-bond process must account for these failure modes and more, among the numerous wire-bond process variables. There are several methods of evaluating and testing wire bonds and wire-bond processes, especially for military, aerospace, and satellite applications, where standards can be extremely rigorous.

Best Practices for Wire Bond Evaluation and Testing

Each application and die may have its own set of parameters and evaluation criteria. If the die is designed for use in military, government, aerospace, satellite, automotive, or other standardized applications, there may be a body of national or international standards to which the wire-bonding process must adhere. These requirements often come with specific evaluation methods and testing procedures.

Typically, these tests may involve internal visual testing, ball-bond shear tests, constant acceleration tests, random vibration, mechanical shock tests, and stabilization bake. Additionally, environmental tests for moisture resistance and temperature cycling may be used. Military standards, specifically MIL-STD-883, detail a wide array of tests and evaluations for U.S. military wire bonds. These include a test for bond strength, the destructive bond-pull test, method 2011.7, and a nondestructive bond-pull test, method 2023.5.

To learn more about how to ensure your best chance at meeting various MIL-STDs through development of best practices and processes for wire bonding, download our Tech Brief "Tips for Increasing Yields When Wire Bonding Small Mesa Chips" now.