Stop by to visit SemiGen and Naprotek at this year's International Microwave Symposium (IMS 2024) from June 16-21 in Washington, DC. We will be showcasing our unique portfolio of EMS capabilities including RF/Microwave electronics (MicroE) assembly, [...] Read More

Naprotek, LLC., a leading provider of high-reliability, quick-turn electronics manufacturing, has completed the acquisition of MicroFab, Inc., a privately held company in Manchester, New Hampshire. This acquisition is a strategic element of Naprotek's [...] Read More

Join SemiGen and Naprotek in person at this year's International Microwave Symposium (IMS 2022) from June 19-24 in Denver, Colorado. We're excited to showcase our unique electronics manufacturing capabilities in booth #12030, conveniently located [...] Read More

Naprotek, A Portfolio Company of Edgewater Capital Partners, Acquires SemiGen Naprotek, LLC, a leading provider of high-reliability, quick-turn electronics manufacturing, has completed the acquisition of SemiGen, Inc., a privately held company [...] Read More

As the spread of COVID-19 continues and the associated policies protecting our citizens continue to evolve, SemiGen is committed to the health and well-being of our employees, customers, and partners as a top priority. SemiGen continues to [...] Read More

Diodes are remarkably simple yet extremely versatile devices, and each type has characteristics that make it well suited for specific applications. One of the less common but nevertheless very useful is the Step Recovery Diode (SRD) whose characteristics [...] Read More

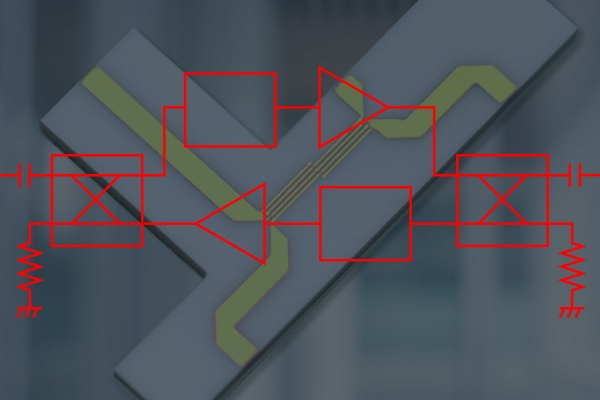

The Lange Coupler was developed by Dr. Julius Lange of Texas Instruments in 1969, while his group was engineering microwave amplifiers on thin film ceramic substrates. The team employed a Bell Labs approach that used 3 dB quadrature couplers, but [...] Read More

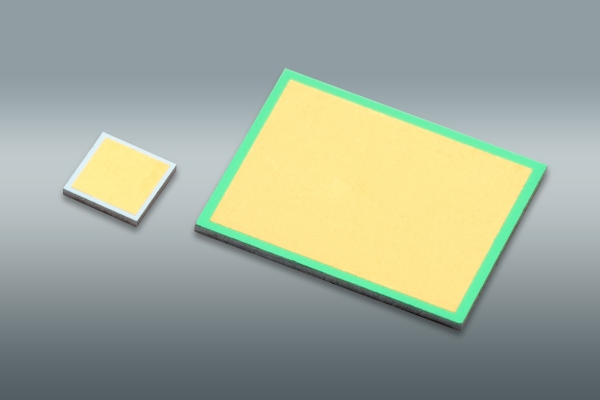

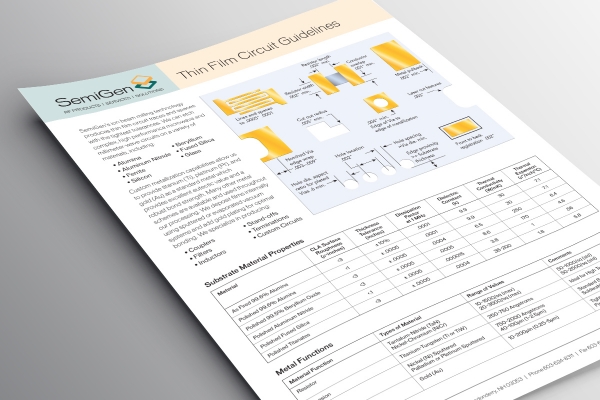

We have released our thin film circuit design guidelines. Designed to help RF, microwave, and millimeter-wave circuit design engineers with optimizing their layouts for our advanced ion beam milling (or etching) process, the layout tolerances and approaches [...] Read More

It’s not uncommon for OEMs to address their RMAs * by leaning towards replacing their returned RF/microwave components, subsystems, and assemblies instead of repairing them. Whether it’s to avoid the hassle of shifting talent around, [...] Read More

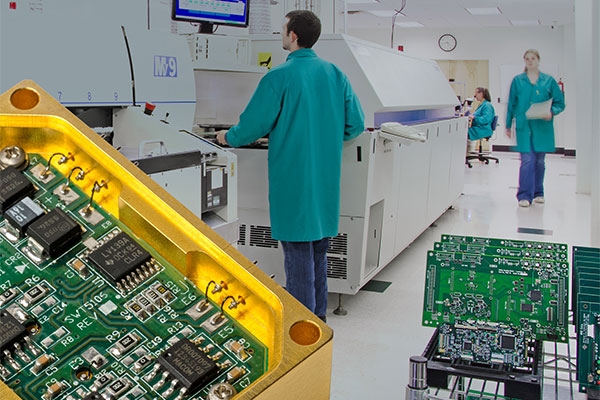

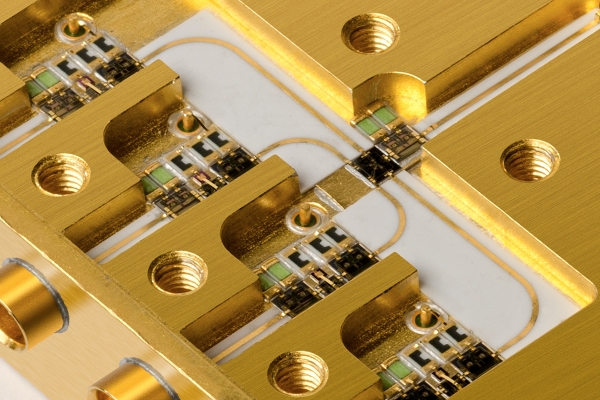

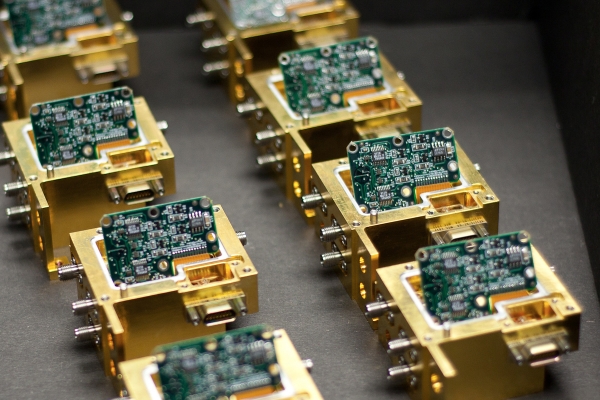

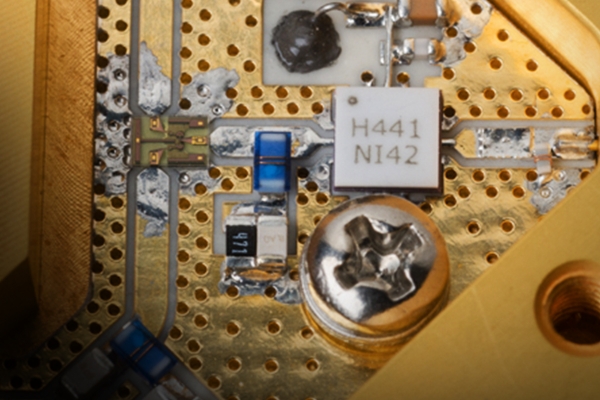

The assembly process can be complex in the production of RF modules with a variety of skills needed to populate components, including: hand soldering; eutectic attachment; ribbon bonding; coil winding; and surface mounting. Ultimately, manufacturing RF, [...] Read More

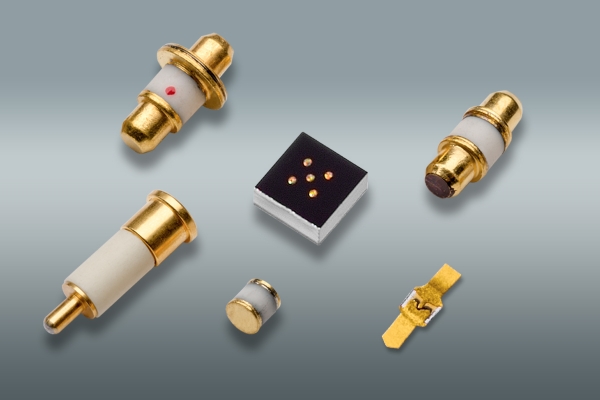

Military and aerospace programs require standardized testing in accordance to various military specifications for quality assurance. This means that all parts need to be screened before integration. This often includes upscreening and specialized application-based [...] Read More

After recently upgrading a new facility, and acquiring Ion Beam Milling, Inc., we are more poised than ever to help RF companies improve their supply chains and bottom lines with an impressive array of on-demand products and services. To [...] Read More

We have released a new Tech Brief "Leveraging the Precision of Ion Beam Milling Vs. Chemical Etching of Thin Film Circuits" that details the advantages to RF/microwave circuit designers of manufacturing their circuits using ion beam milling [...] Read More

The product delivery process is optimized when an RF/microwave manufacturer can optimally leverage the expertise of its team member’s respective specialties. In a busy manufacturing center however, you’ll often find highly skilled design engineers [...] Read More

From the EDI CON 2018 exhibit floor, our President, Tim Filteau brings the RF, microwave, and manufacturing industry up-to-speed on a unique suite of product and service offerings that help manufacturers expand their ability to deliver. (Interviewed by [...] Read More

CEO and Founder of SemiGen, Jim Morgan, interviewed with Everything RF to discuss our history, what differentiates us from other companies in the industry, and our new facility. Jim talks about our growing RF/microwave [...] Read More

We are pleased to announce the acquisition of Ion Beam Milling of Manchester, New Hampshire. Ion Beam Milling is a 35-year-old manufacturing company who pioneered several thin film circuit processing techniques using innovative ion beam [...] Read More

The PIN diode is one of the most versatile types for RF and Microwave designers, which is why it’s used in a broad array of applications from limiters to phase shifters, modulators, attenuators, and switches. In this article we’ll show [...] Read More

The Schottky-barrier diode has become a staple in the microwave designer’s toolkit because its performance is closer to an “ideal” diode than many other types. In this blog, we’ll show you its advantages and disadvantages. For [...] Read More

We are pleased to announce that after moving into our new state-of-the- art facility, we’ve made an additional capital investment of over a half million dollars in new production, wafer fab, and testing equipment to support customer demand. The [...] Read More

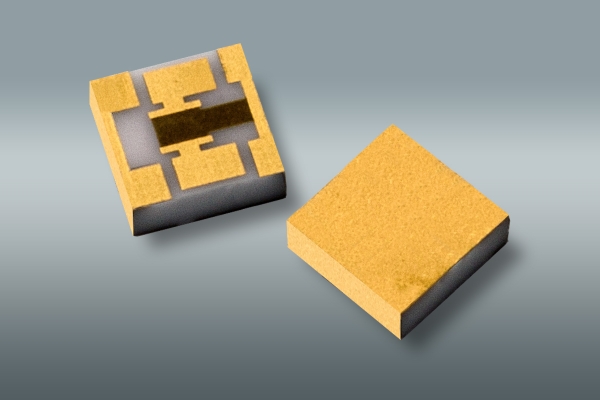

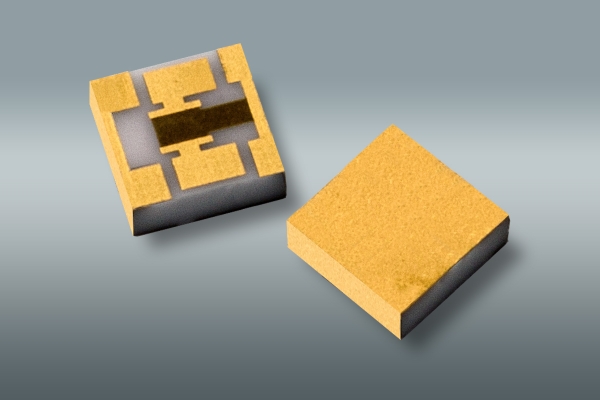

We have announced the publication of a new Tech Brief “Eutectic Die-Attach of GaN and GaAs MMICs.” The latest in RF/microwave GaN and GaAs MMIC circuit chips (die) are providing higher power levels than previous solid-state [...] Read More

The nuances of RF/microwave design, manufacturing, and testing leave little room for error. And shortening the design, development and manufacturing cycle can be especially challenging. But when several production schedules need to be balanced [...] Read More

Our full-service, high-quality, RF/Microwave design and automated assembly services are a viable option for companies looking to reduce assembly cost while keeping their production domestic. Our team provides expertise and experience in the [...] Read More

In our Tech Brief "Tips for Increasing Yields When Wire Bonding Small Mesa Chips" we cover a variety of topics from tools to process development. But one of the more critical tips is about how to spot wire bond failures. In this blog, we've [...] Read More

Tim Filteau Joins SemiGen as President—Aims to Leverage Full-service Capabilities in Growth Strategy

We are proud to announce the hire of our new President, Tim Filteau. Mr. Filteau is an experienced leader who has held executive-level operational positions at RF, Semiconductor, and Integrated Products companies including MACOM, Cobham PLC, and Aeroflex [...] Read More

The advent of smaller mesas (sometimes < 40 microns) on microwave diodes and other devices, and the ongoing push for faster processing speeds and higher yields, have posed a number of wire bonding challenges to RF and microwave designers and manufacturing [...] Read More

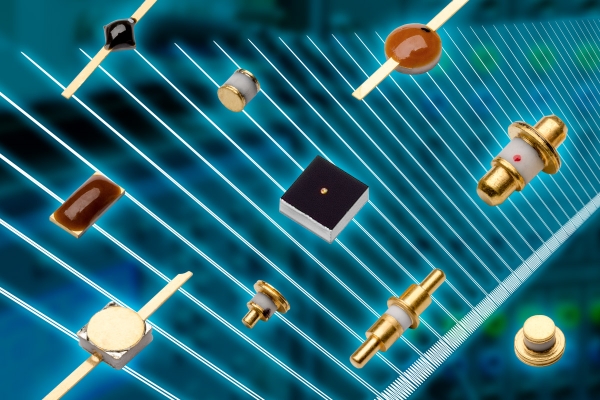

If you've been looking for replacement devices or a new first or second source for your RF and microwave diodes and semiconductors, you can rely on SemiGen. Industry veteran and founder of SemiGen, Jim Morgan, has committed to an RF and Microwave technology [...] Read More

SemiGen, Inc. announces the exciting purchase of the former Micrometrics/Metelics fabrication facility in Londonderry, New Hampshire. Moreover, SemiGen will be relocating operations to this location. The recently acquired facility boasts 43,000 square [...] Read More

The bond pad geometries for MESA chips are shrinking in size progressively as technology advances. Though beneficial for cost reduction and mass production, smaller MESA chip leads and bonding sites exacerbate the failure modes common to a wire bond process. [...] Read More

SemiGen, Inc. announces a new Technical Brief, “Tips for Increasing Yields when Wire Bonding Small MESA Chips,” discussing the challenges of wire bonding to small MESA chips. This latest brief provides insights into the wire bonding process [...] Read More

The increased cost and complexity of designing, prototyping, assembling, troubleshooting, and redesigning modern RF/microwave assemblies that meet stringent government, military, and aerospace requirements is leading to a substantial growth in US-based [...] Read More

From fixing broken equipment to new RoHS requirements leading to part obsolescence, original equipment manufacturers (OEMs) in the RF and microwave industry have many reasons to replace modules over repairing them. Often, predicting the services necessary [...] Read More

SemiGen, Inc. has added a series of new Zero Bias Schottky Detector Diodes to its expanding product offerings. SemiGen’s SZB900 series of Zero Bias Schottky Detector Diodes are catered to perform as components of video detectors [...] Read More

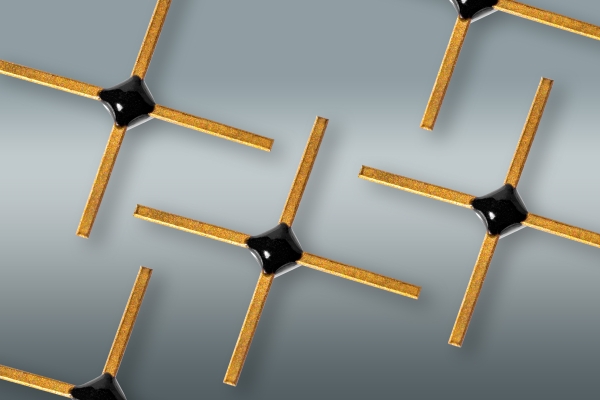

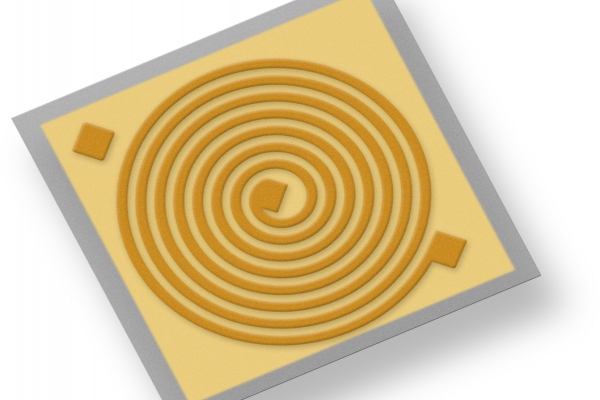

SemiGen spiral inductor coils come in ten models with seven different square dimensions including .030”x.030”, .040”x.040”, .045”x.045”, .055”x.055”, .065”x.065”, .075”x.075”, and [...] Read More

As in baseball, RF/Microwave programs are dotted with holes in the lineup, or development chain, from design to repair. Oftentimes, problems arise out of nowhere, and at critical times. In these circumstances, each field is glad to have their utility [...] Read More

SemiGen’s ideal low loss very high Q MIS capacitors feature low temperature coefficients. With six different capacitances offered from 45 pF to 1000 pF, these capacitors are developed using an MNOS approach and precision photolithography to provide [...] Read More

SemiGen, Inc. has added a series of new Schottky Diodes to its expanding product offerings. SemiGen Silicon-based Schottky Diodes utilize various metal schemes to provide excellent performance for low, medium and high barrier applications through [...] Read More

The 1N series point contact mixer diodes perform into the Ka-band. Each device in the series ideally designed with noise figures as low as 5.5 dB at 3.060 GHz and 6.0 dB at 9.375 GHz. With VSWR’s of 1.3:1 and impedances ranging from 200-600Ω, [...] Read More

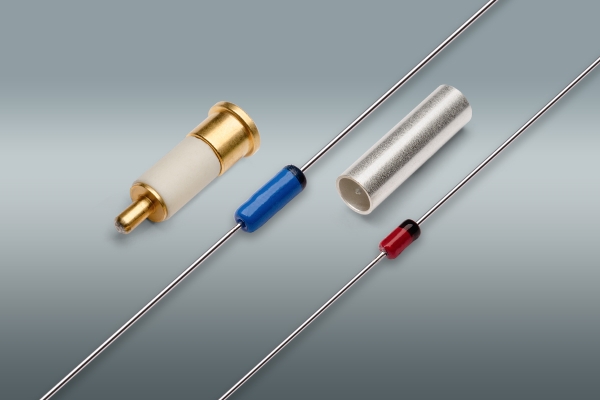

Step Recovery Diodes (SRDs) utilize controlled grown junction epitaxial silicon combined with a silicon dioxide passivation to ensure greater stability and reliability. Our SRDs offer low snap time through voltages ranging from 8 VDC to 120 VDC. Capacitances [...] Read More

SemiGen, Inc. has added a series of new limiter diodes to its expanding product offerings, SLP7100 series. The SLP7100 limiter diodes are processed with a high-resistivity epitaxial wafer (epi) that has thin intrinsic layers. These [...] Read More

SemiGen now offers a series of Beam Lead PINs, the SBL 2000. The SBL2000 beam lead PIN diodes feature switching speeds as low as 3 ns with both low capacitance and resistance. SemiGen’s beam lead PINs are optimally designed during [...] Read More

Limiter, Schottky, Step Recovery and Point Contact Diodes The SLP7100 series limiter diodes feature a low capacitance, resistance and quick turn on times. These limiters are ideally suited for high-power applications as protection against unwanted [...] Read More

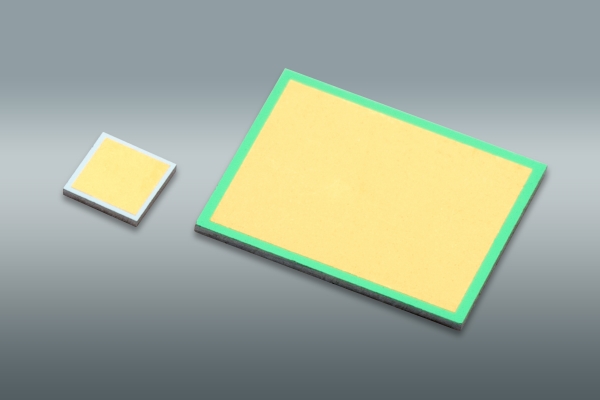

SemiGen offers a selection of fixed attenuators pads with an attenuation of 0 dB up to 100 dB. These attenuator pads feature precise resistor films and superior metallization resulting in a flat response from DC to up to 50 GHz. Attenuator pads offer [...] Read More

SemiGen has announced that a series of MIS capacitors are now available. Series 8000 capacitors offer a working voltage of >50V and capacitance ranges from 2.0 pF to 600 pF. Series 8100 capacitors offer a working voltage of >100V and [...] Read More

SemiGen has announced that they have purchased a new Agilent 50 GHz PNA Network Analyzer to augment their RF/Microwave test lab. SemiGen's facility will now have the ability to provide higher frequency testing for internal designs and customer requirements. The [...] Read More

SemiGen provides high-quality, automated PCB assembly for high-mix, low- to medium-volume printed circuit boards. SemiGen helps manufacturers of military electronics, commercial products, and medical instrumentation with their leadless, fine-pitch, BGA, [...] Read More

SemiGen offers PIN diodes that feature low capacitance and resistance, high reliability, and easy bonding with F.A.C. mesas. SemiGen's new RF Supply Center provides high-quality PIN diodes that can be shipped or ordered for kits on the SemiGen floor. [...] Read More

SemiGen has announced that a series of fixed attenuator pads are now available. SemiGen's advanced thin-film technology allows these attenuator pads to have full side wraps for SMT installation and a complete grounding backside for ease in attachment. [...] Read More

.jpg)

.jpg)

.jpg)

(2).jpg)

.jpg)

.jpg)